Fiberglass armature:

* by clicking on the photo, you are going to be directed to a video where you'll see how to roll out the fiberglass armature correctly*

Fiberglass armature in the market appeared relatively recently, and the builders just did not have time to understand the benefits of its application. The advantage is based on a relatively cheap price thanks to the lighter delivery and installation, and due to the fact that the material has many good properties.

Main benefits:

1. 20-60% cheaper than metal armature;

2. 10 times lighter than metal armature;

3. 3.5 times more durable than metal armature;

4. Stainless, non-reactive to bases and acids (concrete - basic environment!)

5. Non-conductive, non-magnetized, the usage if this materila will not interrupt electromagnetic waves

6. High elasticity => Resistant to earthquakes

7. It is tens of times more durable than metal

8. Transportation is up to 20 times cheaper and more convenient.

9. Ecological building material

10. No thermal conductivity

Application:

1. The whole spectrum of house constructions: monolithic bases, strips, rural roads, walls and planks, elastic connection in three-layer walls or exterior claddings, garden plants, bars for support, etc.

2. Construction and industry in buildings and structures are used in concrete structures.

3. For use in lightweight and heavy concrete, aerated concrete, slabs, base plates or base plates which are capable of reducing the concrete protective layer due to resistance to aggressive media, including those containing chloride salts, bases and acids.

4. Brick masonry buildings, including trees (flexible joints), building walls and three-layer walls for external insulation to increase the energy efficiency of the structure (400 times the thermal conductivity).

5. As grids and bars in structures.

6. Use in close contact with water: in coastal protection, in rivers, lakes, seas and harbors; pools, fountains, drains, sewers, etc. (it is immune to an aggressive environment, including those containing chloride salts, bases and acids).

7. Improvement of drainage and drainage (not susceptible to aggressive environments, including those containing chloride salts, alkalis and acids).

8. On the road base: it is non-responsive to road reagents, road surface life increases by 30-35%, vertical loads become horizontal, reduce the amount of cracks, increases between repair periods.

9. Buildings and structures in both existing and newly built roofs. It is recommended for use in any facility with high vibrational working conditions (nuclear power plants, hydroelectric power stations, bridges, etc.). In Japan, the use of metal in seismically active areas is prohibited.

10. Products made of concrete with pre-stressed and non-power reinforcement (lighting supports, power transmission lines, insulation overhead lines, road and cobblestone plates, fencing boards, curbs, rail sleepers, shaped manifolds, pipelines and ducts).

11. Heating house installation.

12. Elements of the chemical industry.

The use of composite reinforcement increases the structure life time 2-3 times compared to the use of metal fittings, especially when affected by aggressive factors including vibrations, salts, slags and acids.

| Armature | ||

| Metal group А-III (А400 - 25Г2С) | Fiberglass reinforcement for composite polymeric materials | |

| Material | Steel | Glazing with epoxy-based polymer |

| Deformation | Flexible plastic | Ideal - Flexible |

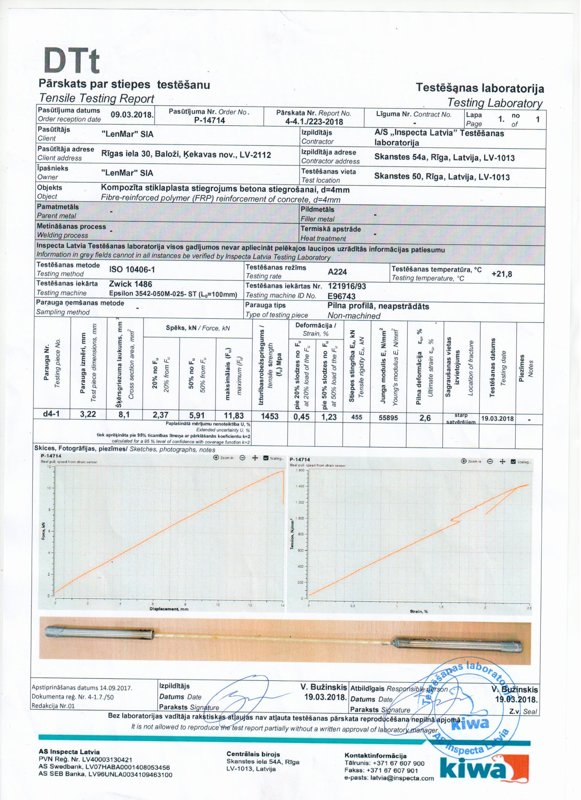

| Tensile strength, MPa | 390 | 1 300 |

| Flexibility module, MPa | 210 000 | 55 000 |

| Relative Extension,% | 25 | 2.2 |

| Thermal conductivity coefficient, W / (m ≈ 0 C) | 46 | 0,35 |

| Linear expansion coefficient, αх10-5 / 0С | 13-15 | 9-12 |

| 7850 | 1900 | |

| Corrosion resistance to aggressive materials | Subject to corrosion | Stainless material |

| Thermal Conductivity | Rusts | non-conductive |

| Electrical conductivity | Electrically conductive | Non-conductive - is dielectric |

| Produced profiles | 6 - 80 | 4 - 20 |

| Length | 11.7m | On request. See the sizes below. |

| Ecological compatibility | Nature friendly | None toxic, belongs to 4. Hazard class (low risk) |

| Resistance | In accordance with construction standards | Estimated strength for at least 80 years. |

| Ø 6 А-III | Ø 4 АКС | |

| Ø 6 А-III - 0,222 | Ø 4 АКС– 0,02 | |